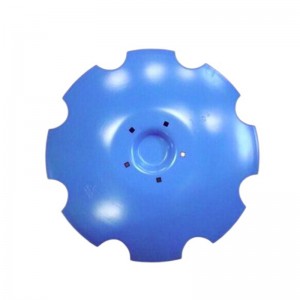

Rake discs – an efficient tillage tool for soil treatment

The harrow disc is the core working component of a tractor-mounted or suspended disc harrow. It is a disc-shaped blade that cuts, crushes, and turns the soil through high-speed rotation. It is mainly used for post-plowing land preparation, chopping crop residues, weeding, fertilizer mixing, and seedbed preparation. It is a key link between deep plowing and sowing, creating a loose, level, and moisture-retaining seedbed for crops.

1、Fine land preparation: Breaks up large clods of soil after plowing, levels the land, and forms a fine, uniform topsoil layer.

2、Stubble treatment: Sharp blades effectively chop up crop stubble such as corn and rice, promoting straw return to the field and decomposition.

3、Shallow mixing: Evenly mixes topsoil fertilizers, pesticides, or mulch with the soil to improve utilization.

4、Weeding and loosening the soil: Cuts weed roots, breaks up soil compaction, and improves soil aeration and water permeability.

5、Moisture retention and drought resistance: Creates a loose topsoil layer, breaks capillary action, and reduces soil moisture evaporation.

Main body material: Made of high-quality high-carbon steel (such as 65Mn) or alloy steel to ensure high strength and toughness.

Cutting edge treatment: The cutting edge undergoes a special quenching and tempering process, resulting in high hardness (up to HRC 40-50 or higher), strong wear resistance, and long service life.