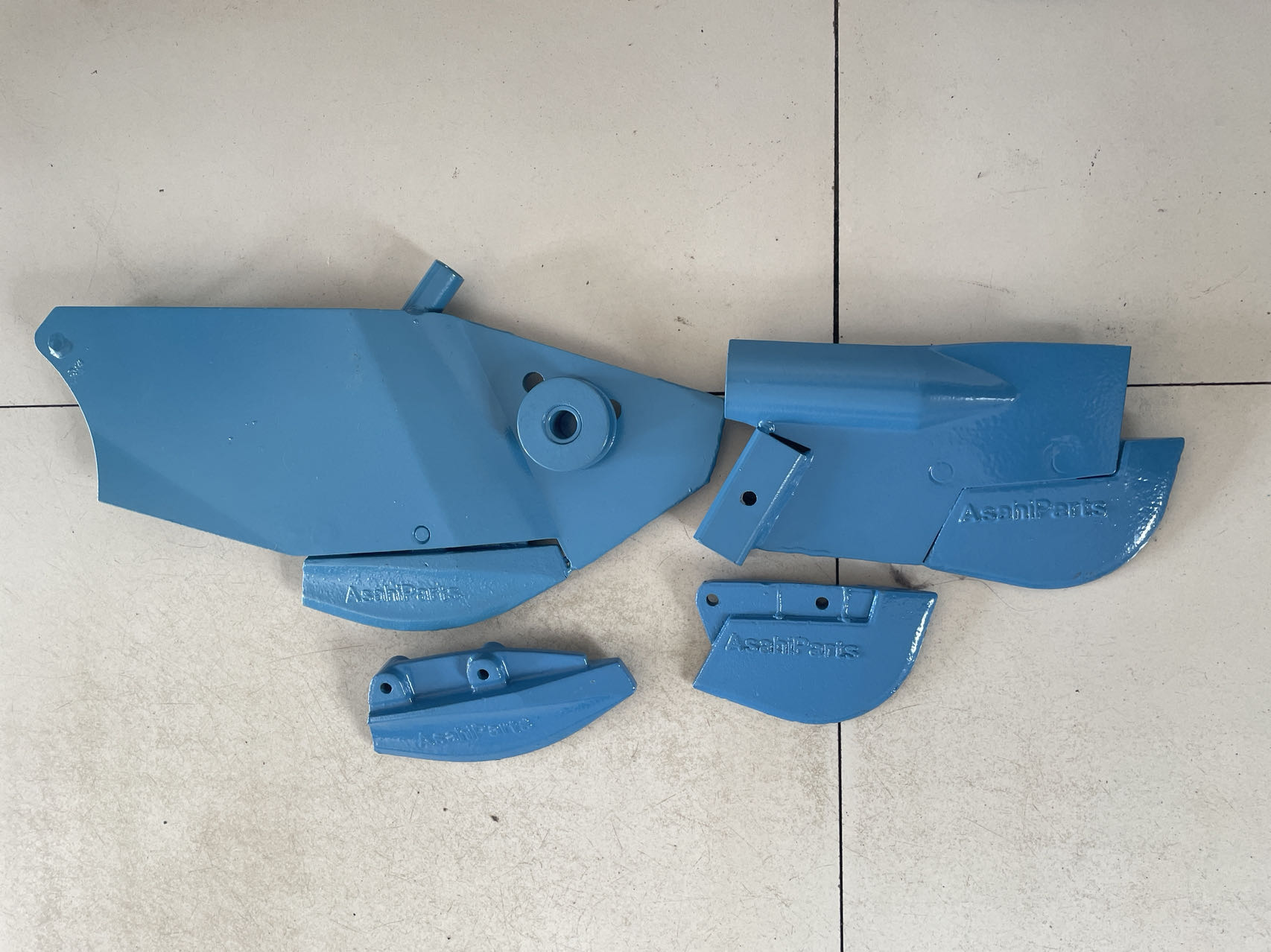

High-quality cast steel parts,Wear-resistant parts

The production process of cast steel parts is the process of casting steel water into the required shape parts. The main steps are as follows:

1. Preparation of raw materials: Select suitable scrap steel, cast iron and other raw materials, and adjust the composition according to the requirements of the casting to ensure that its mechanical properties (such as strength and toughness) meet the standards.

2. Smelting: Send raw materials to steelmaking furnaces (such as electric arc furnaces and induction furnaces) for melting, control the temperature (usually 1500-1600℃) and chemical composition, remove impurities (such as sulfur and phosphorus), and obtain qualified steel water.

3. Molding core: make molds and mold cores according to the shape of the parts. Common methods include sand casting (sand materials are mostly quartz sand with binder), metal casting, etc., and the core is used to form internal cavities or complex structures of parts.

4. Pouring: Pour the melted steel water into the mold cavity and wait for it to cool down and solidify to form a casting blank. When pouring, the speed and temperature should be controlled to avoid defects such as insufficient pouring and shrinkage.

5. Sand cleaning: After the casting cools down, remove the mold and the mold core (such as vibrating sand), clean up the burrs on the surface, pouring mouth, etc., and obtain the preliminary molded castings.

6. Heat treatment: heat treatment such as annealing, positive fire, quenching, etc. according to demand to improve the internal organization of the casting and improve its mechanical properties (such as eliminating internal stress and improving hardness).

7. Subsequent processing: Through cutting (such as turning, milling, grinding), surface treatment (such as painting, electroplating), etc., the parts meet the dimensional accuracy and surface quality requirements of the design.