High-performance flail cutter – a powerful tool for grass and straw processing

The flail knife is an important cutting auxiliary part in agricultural machinery, mainly used for straw crushing, weed clearing, orchard pruning, etc. It is made of high-strength alloy steel or wear-resistant manganese steel, and after heat treatment and precision processing, it has excellent hardness, toughness and wear resistance, and can adapt to high-intensity continuous operation.

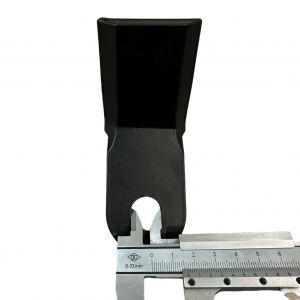

There are various designs of flailing blades, including straight blade, curved blade and sawtooth blade, which can be selected according to different operation requirements. It has excellent dynamic balance performance. When installed on the rotating shaft and running at high speed, it has high cutting efficiency, evenly chopped grass, and effectively reduces power loss. Some models are equipped with replaceable blades or reversible designs to extend service life and reduce maintenance costs.

It is suitable for straw returners, mowers, silage machines and other equipment, and is widely used in wheat, corn, rice and other crop straw processing, as well as pasture and orchard vegetation management. It has the characteristics of simple structure, convenient disassembly and assembly, strong compatibility, etc., and is an ideal accessory for improving the efficiency of agricultural machinery operations.

1、Extraordinary Wear Resistance and Durability

High-Quality Materials: Made from high-strength alloy steel (such as 60Si2Mn, 65Mn) or special wear-resistant steel, the blade is tough.

Advanced Technology: The blade undergoes precision forging and full heat treatment to ensure uniform hardness both inside and out. The handle maintains its toughness to prevent breakage, while the blade undergoes a special quenching or surface carburizing treatment to achieve an extremely high hardness (HRC 58-62 or higher), increasing wear resistance by over 50%.

2、Efficient Cutting and Crushing

Dynamically Balanced Design: Precision aerodynamic design ensures smooth and stable high-speed rotation, reducing vibration and power loss for higher cutting efficiency.

Sharp Edge and Unique Blade Shape: Optimized blade angles ensure rapid penetration and minimal cutting resistance. A variety of blade shapes (such as L-shaped, Y-shaped, and hammer claw) enable the multi-functionality of "chopping, slicing, tearing, and shredding" for different materials, resulting in uniform particle size and excellent distribution.

3、Wide Applicability

Multi-Crop Handling: Perfect for crushing and returning hard straw, such as corn, wheat, and rice, to the field. It's also suitable for harvesting and chopping forage grasses like alfalfa and king grass.

Multi-Working Conditions: Stable performance on both flat fields and rugged slopes. Effectively handles fallen crops and tangled weeds.

4、Easy installation and simplified maintenance

Standardized design: Fully compatible with leading brands and models of straw returners and mowers.

Modular mounting: Typically secured with pins or bolts, it's easy to remove and replace without the need for special tools, significantly reducing downtime for maintenance.

5、Significant Economic Benefits

Long Service Life: Superior wear resistance means longer tool replacement cycles, effectively reducing tool costs and labor-intensive tool changes per operation.

Improved Machine Efficiency: Efficient shredding aids subsequent tillage operations, promotes rapid straw decomposition, increases soil organic matter, and contributes to sustainable agricultural development.